A MUSEUM FOR THE RESTORATION AND REUSE OF FINNISH LOG STRUCTURES

This proposal outlines a museum designed to support the restoration and preservation of Finnish timber structures and traditional construction methods within the Seurasaari Open-Air Museum in Helsinki, Finland. Finnish log construction has been a fundamental building technique for millennia and has shaped the country’s architectural history. However, with the rise of standardised, mass-produced timber, many traditional log-built saunas and summer cottages have been abandoned across Finland’s forests.

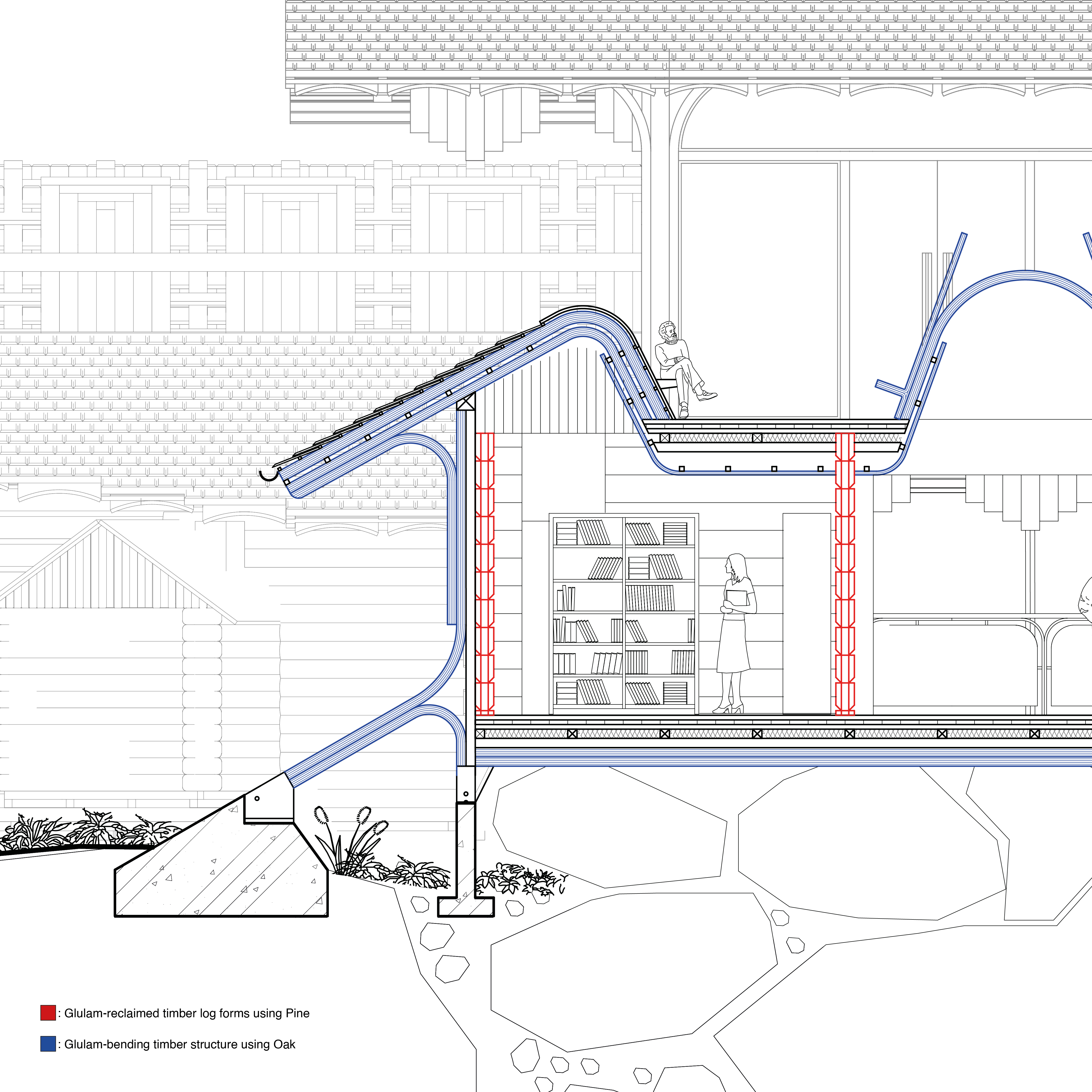

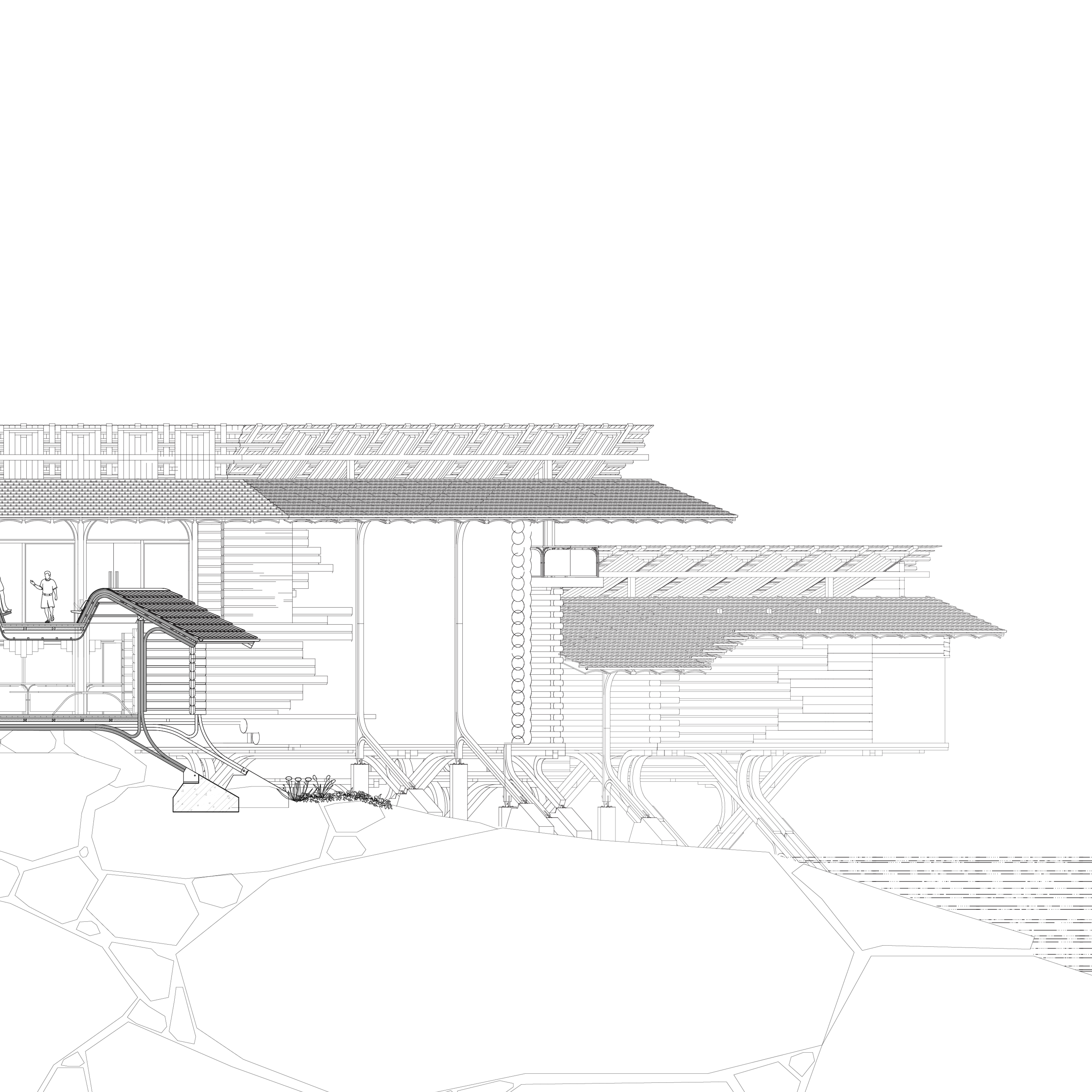

The project acts as a physical repository for these abandoned timber structures and building fragments, enabling their conservation and reinterpretation while safeguarding Finland’s log architectural heritage. The primary structure is conceived in log construction, with one structural system formed from reclaimed glulam timber logs to demonstrate the potential of timber reuse. This approach aims to increase the value of demolition materials by repurposing secondary timber elements into primary structural components for new buildings.

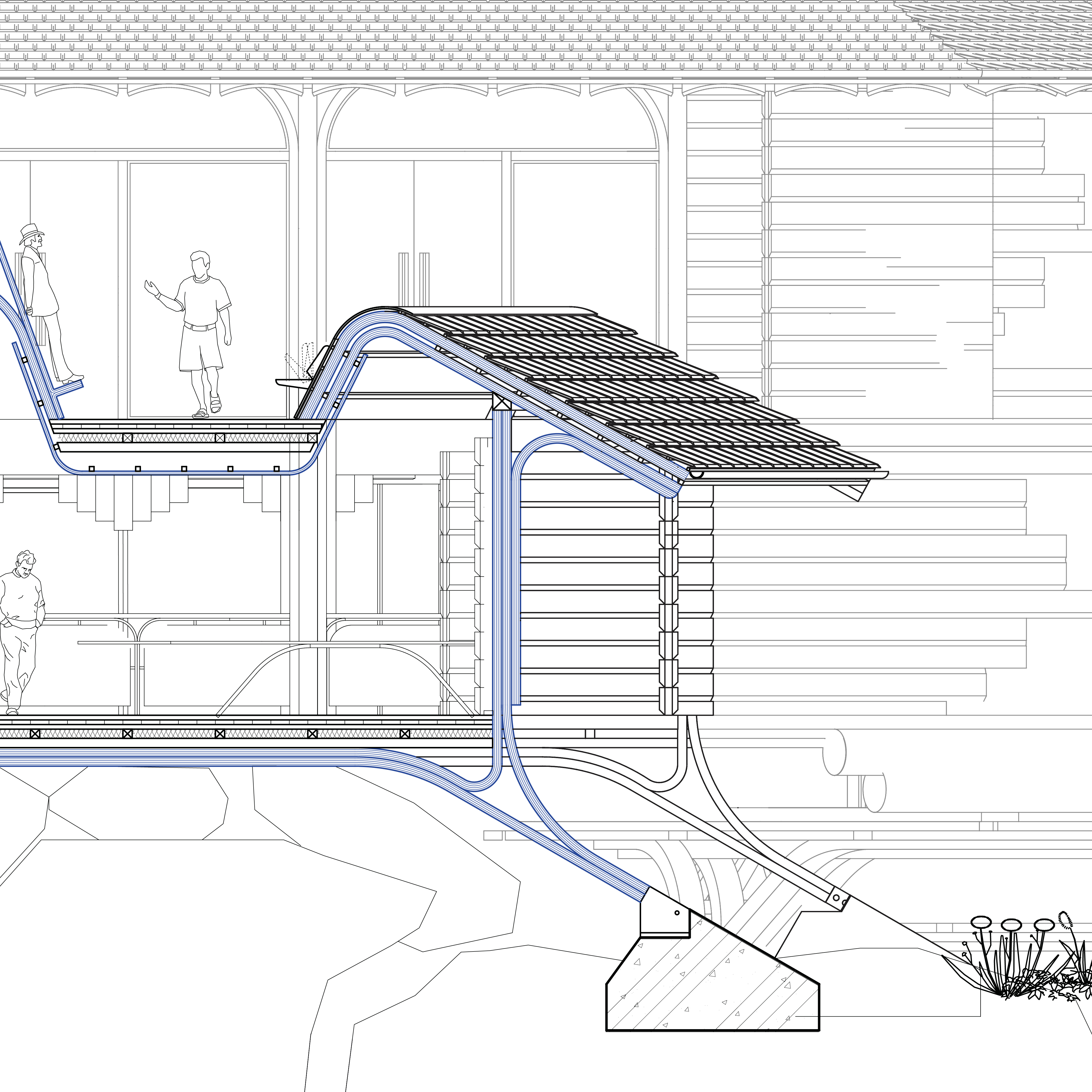

The application of bent glulam timber for the external and roof structures establishes an innovative structural relationship, highlighting both material efficiency and contemporary possibilities in timber architecture.

STRUCTURAL AND AESTHETIC BENEFITS OF GLULAM BENDING TECHNIQUES WITH RECLAIMED TIMBER

The glulam technique is employed throughout the entire structure, from the curved footing to the bending roof. All timber components shaped using reclaimed log forms rely on this method. Glulam construction offers remarkable flexibility, allowing for a wide range of shapes and dimensions while maintaining a refined, visually appealing character—even across long spans.

Because timber performs optimally when loads follow the grain, bending wood rather than cutting it often results in greater material efficiency, durability, and structural performance. By applying glulam bending strategies to both the exterior and the roof, a strong, resilient structure can be formed using reclaimed glulam logs. This approach also creates a new design dialogue between the bent glulam elements and the reclaimed log forms, enhancing both structural performance and architectural expression.

FROM RECLAIMED LOGS TO STRUCTURAL PRECISION: A DIALOGUE BETWEEN WOODS

The project uses two types of wood in different ways. Reclaimed pine logs are used for the glulam forms, while oak—a much stronger hardwood—is used for the glulam structure that shapes the exterior and roof. Together, these materials create a unique system where softwood and hardwood work in balance, both visually and structurally.

By combining different types of timber, the design enhances both the structure's appearance and performance. The oak glulam parts provide strength and precision, while the pine logs add warmth and character. This mix shows how reclaimed and engineered wood can be given new life through modern construction and fabrication methods.

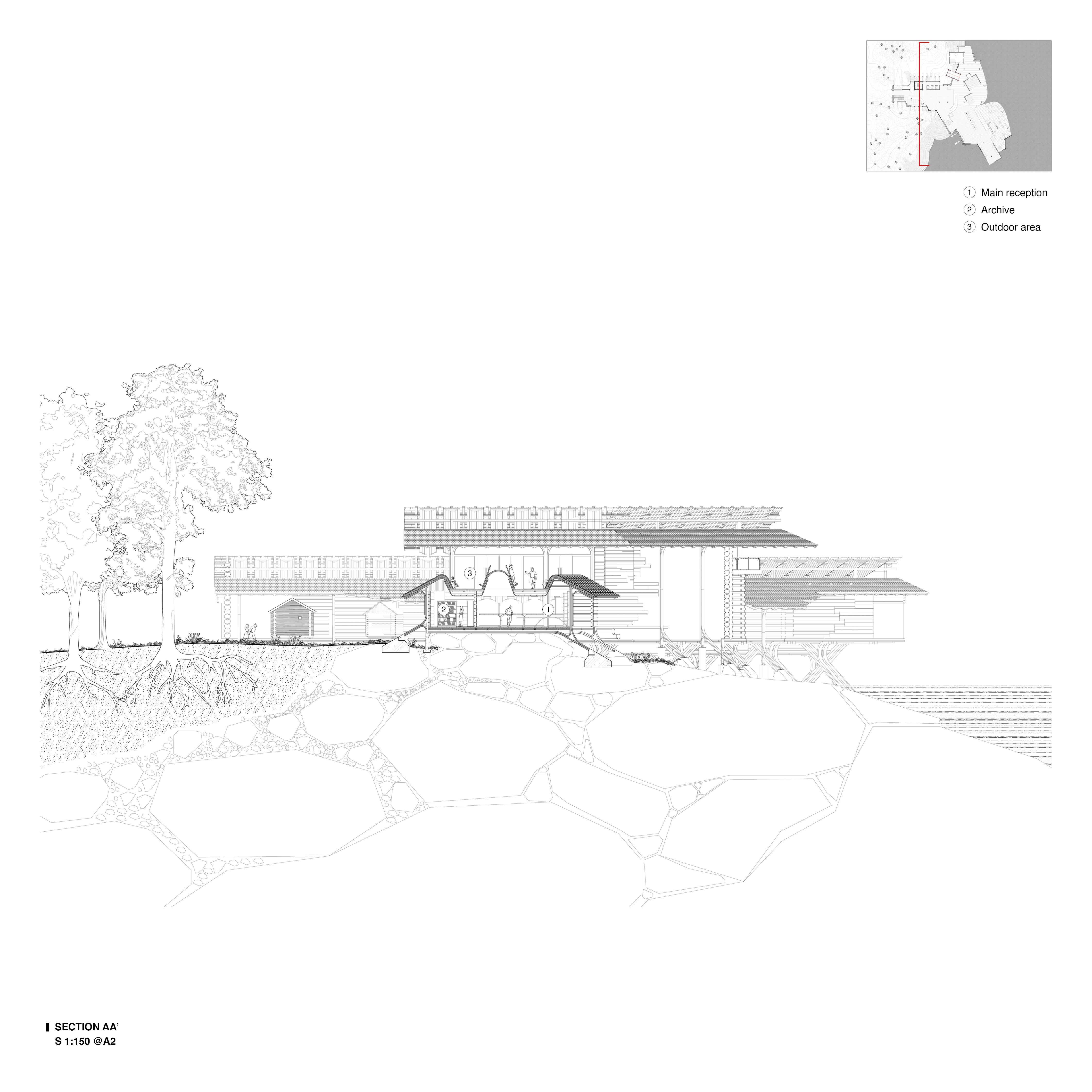

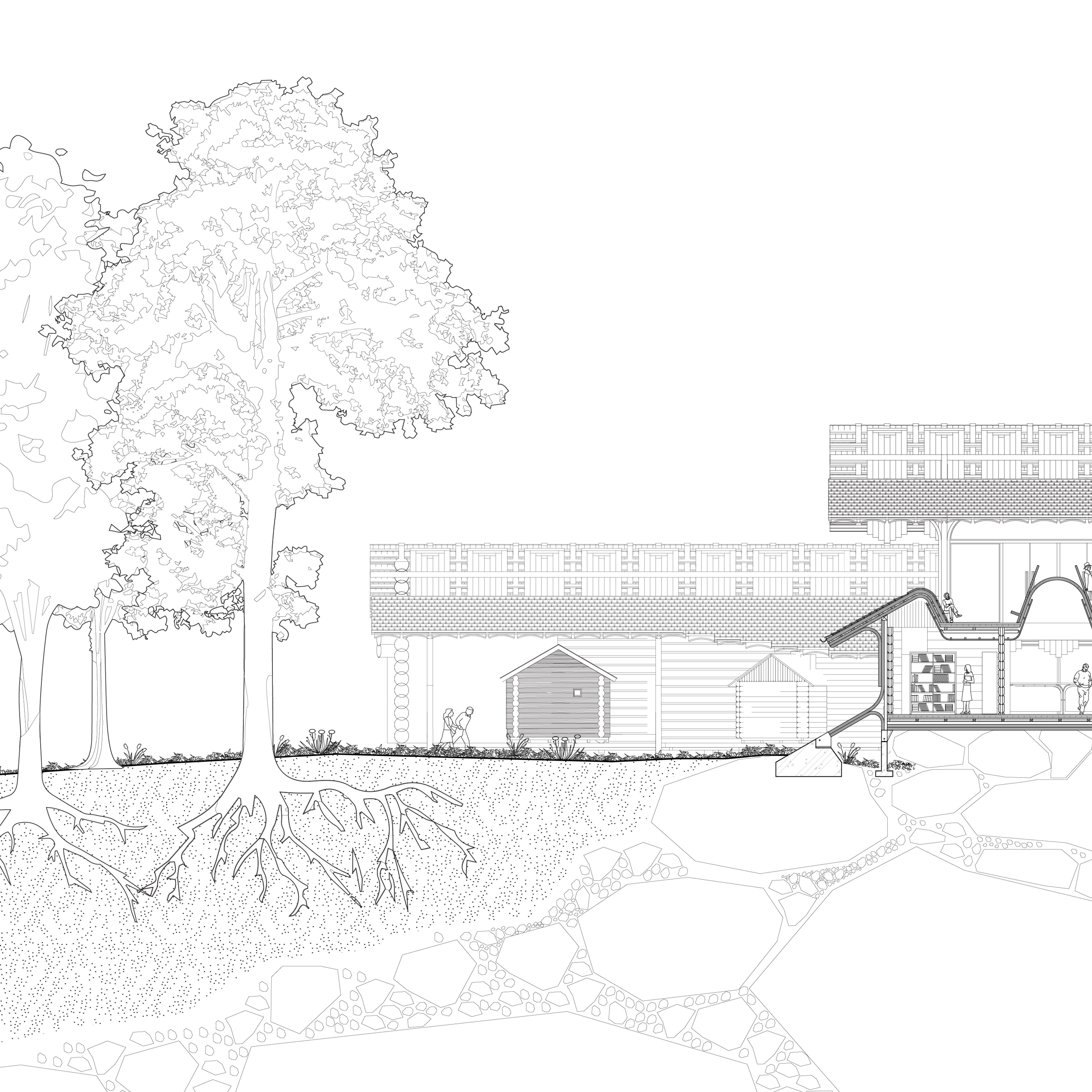

NEGOTIATING TERRAINS: ADAPTING ARCHITECTURE ACROSS FOREST, GRANITE, AND SEA

The museum’s primary programs include collections of log construction and traditional tools, as well as an archive and reception area. The design evolves in response to the distinct requirements of each program, their spatial relationships, and the surrounding environmental conditions.

Spanning across coastal waters, granite formations, and forested areas, the project engages with diverse natural settings, each offering a unique character. A central focus of the design is how the architecture adapts to these varying terrains—the forest floor, rocky coastline, and water. The structural system is developed using a bending timber prototype derived from early material experiments, enabling the building to respond sensitively to different site conditions. Accordingly, the foundation design and material selection are adapted to suit the specific ecological context of each location.

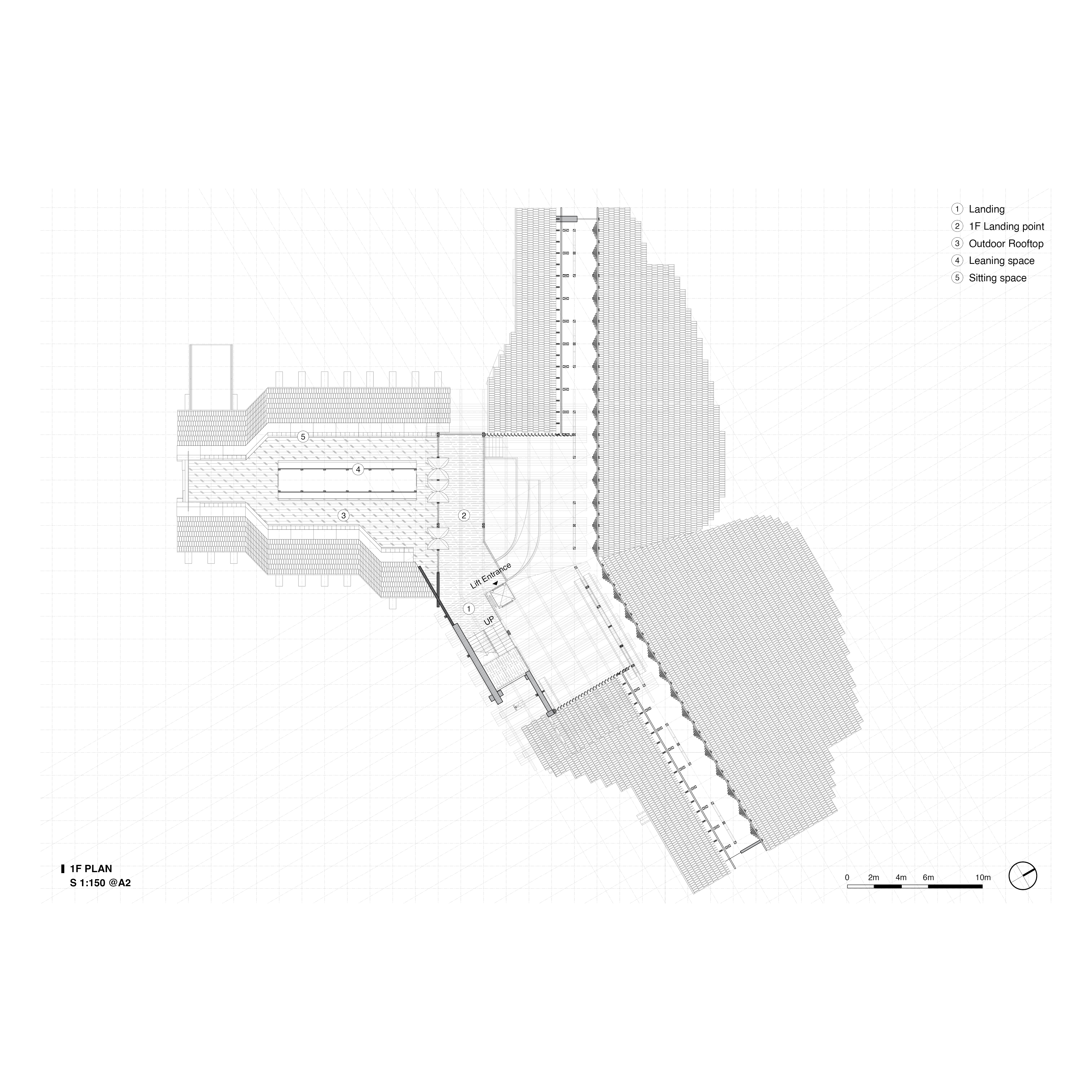

THE OUTDOOR SPACE THAT BRINGS SEURASAARI’S NATURE CLOSER

Located on the first floor, the outdoor area is designed to immerse visitors in the natural surroundings of Seurasaari Island. It’s a place where people can experience the ocean breeze, the trees, and the open sky while sitting on a simple folding chair and resting against a wooden panel. The space is meant purely for visitors to relax and connect with nature.